The modern American manufacturing sector has made huge strides through technological advancement and new innovations in production machinery. The metal stamping industry is no exception, of course, offering a wealth of technology that far surpasses the capabilities of traditional press systems used in decades past. From advancements in automation to emerging developments in materials science, many of today’s metal stamping companies have decidedly entered Industry 4.0

At Keystone Friction Hinge (KFH), we have continually embraced the latest production technologies in metal stamping and beyond since 1905. With more than 115 years of quality-backed service under our belts, today our 88,000 sq.-ft facility is optimized to provide our customers with the utmost in manufacturing flexibility, efficiency, and precision.

Below, we’ll take a look at some of the latest and most critical technologies at the forefront of the modern metal stamping industry.

Automation, Quick Die-Change Systems, and Other Advanced Metal Stamping Technologies:

Smart Manufacturing and Industry 4.0

Metal stamping operations have increasingly adopted smart manufacturing principles and processes in conjunction with Industry 4.0. This largely includes the incorporation of sensors in production, real-time data analytics, and cross-shop connectivity to enhance monitoring, control, and overall efficiency of our metal stamping services.

Advancements in Materials Science

The development of new and advanced materials like high-strength alloys and exotic metals has greatly impacted the metal stamping sector. New materials mean new types of products with greater performance potential. However, these materials often require specialized stamping techniques and custom tooling designed specifically for the job at hand.

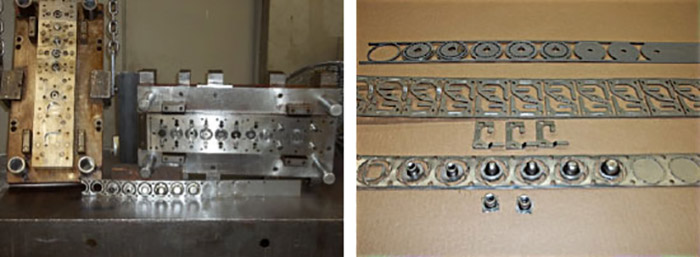

Custom Tool Design and Building

Modern computer-aided design (CAD) systems have streamlined the custom tooling process, allowing us to manufacture complex, highly customized tools easier and more cost-effectively than ever. KFH designs and builds custom tooling in-house to meet each customer’s unique production requirements. Our integration of CAD and CNC technology combined with unparalleled craftsmanship ensure precision-built tooling solutions for every job.

Precision Micro Stamping Techniques

Advancements in precision stamping and micro-stamping techniques allow us to efficiently produce smaller and more intricate components. Compared to when we started in 1905, today we can offer much higher precision in micro-manufacturing, delivering tighter tolerances and better repeatability.

Quick Die-Change (QDC) Systems

The integration of quick die-change (QDC) systems reduces downtime during the changeover of stamping dies, substantially reducing cycle time and increasing capacity for high-volume stamping runs. Quality and repeatability are also further improved by removing the element of human error from the tool changeover process.

A Growing Emphasis on Sustainability

There’s a growing emphasis on sustainability in virtually every corner of the manufacturing industry. That’s why many advancements in metal stamping technology focus on reducing energy consumption and material waste along with the overall carbon footprint.

In many ways, higher sustainability is the natural byproduct of technological innovation due to the increased efficiency and reduced waste offered by the evolving production processes. At KFH, we further embrace sustainability through our lean, highly efficient American manufacturing solutions.

Quality American Metal Stamping Services Since 1905

For more than 115 years, KFH has delivered high quality metal stamped products and custom assemblies that not only meet but exceed our customers’ requirements. From concept through prototyping to full production, we utilize some of the latest technologies in metal stamping and machining to streamline your project and simplify your supply chain.