Wire EDM services provide a number of unique advantages that make it a preferred choice for CNC machining in various high-precision applications. From difficult-to-machine materials to exceptionally complex geometries, wire EDM gives our shop enhanced machining capability and flexibility in combination with our conventional CNC machines.

Founded in 1905, Keystone Friction Hinge (KFH) is backed by more than 115 years of quality American manufacturing services. Along the way, we’ve expanded our capabilities and refined our metalworking processes to keep pace with the ever-evolving needs of today’s high-tech market. The integration of precision wire EDM services has been a natural evolution in our complex machining capabilities.

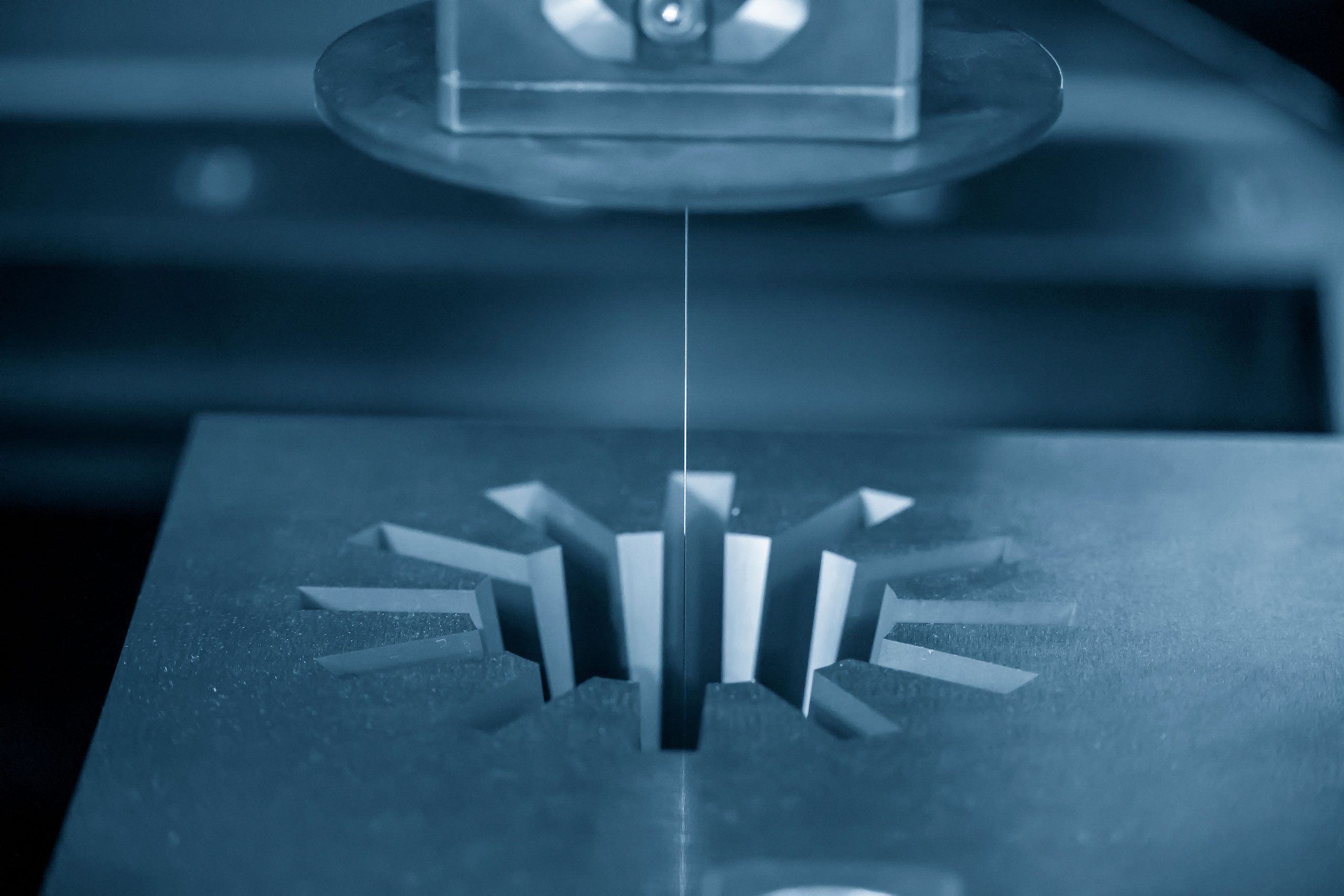

Makino U6 Wire EDM: High-Speed Machining with High Repeatability

KFH’s integrated CNC machine shop utilizes Makino’s U6 wire EDM system to deliver +/-0.0015” accuracy in high-precision machining projects. The U6 wire EDM enhances our custom machining services with an exceptional balance of production speed, repeatability, and surface finish.

- Tolerance Held – between =/- .0005” and .0015” depending material thickness

- Table Travel – 25.6” x 17.7” x 16.5”

- Maximum Workpiece Size – 39.4″ x 31.5″ x 16.5″

- Maximum Workpiece Weight – 3,307 lb

The Advantages of Our Wire EDM Services:

High Precision, Accuracy, and Repeatability

The wire EDM process helps us to achieve exceptionally high levels of precision, in the range of ±0.0015 inches. This extreme accuracy makes our wire EDM services suitable for custom machining applications where the tightest tolerances are required.

Tackling Complex Geometries

Our wire EDM reliably produces intricate and complex shapes that may be difficult or impossible to achieve with conventional machining methods. That includes sharp corners, fine details, and narrow slots. Wire EDM’s CNC integration gives us precise control over the taper angle, allowing for the machining of tapered features with high accuracy.

Machining Hardened Materials and Difficult-to-Machine Metals

Wire EDM is an especially effective method for machining hardened materials such as specialized tool steels, titanium, and carbides. These extremely hard materials can be relatively difficult to machine accurately and consistently using conventional cutting tools and CNC machining processes.

Minimizing Material Distortion

Since the wire EDM process is non-contact and does not generate cutting forces, there is minimal mechanical stress exerted on the workpiece. That reduces the risk of workpiece distortion or deformation, further improving our machining accuracy and repeatability while minimizing manufacturing errors.

Reducing the Heat-Affected Zone

Unlike traditional machining methods, wire EDM generates minimal heat during the process, reducing the likelihood of thermal damage to the workpiece. This is particularly advantageous for heat-sensitive materials.

Achieving a Premium Surface Finish

Our wire EDM services achieve relatively fine surface finishes, often better than what can be readily achieved with conventional machining methods. The result is a reduced need for secondary finishing operations, potentially saving your project additional time and money in post-production.

Quality American Machining Services Since 1905

For more than 115 years, KFH has produced precision-built metal products using a wide range of manufacturing technology. From metal stamping to custom machining, from prototyping to full production, we utilize the latest production technologies to simplify and streamline your project.