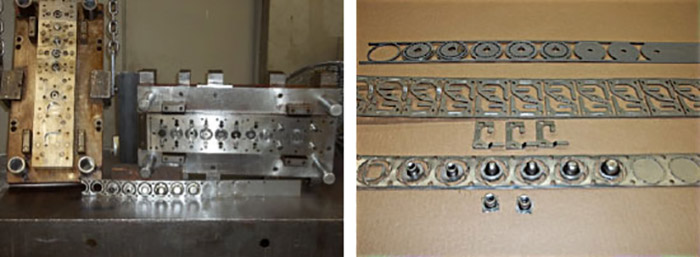

Die Design & Metal Stamping Services

We offer premium tool and die design and manufacturing services that are used for the production of Metal Stampings dies, assemblies and production parts. Keystone has a fully operational tool and die shop which works from concept through prototyping to full production. Keystone Friction Hinge possesses a fully-equipped, traditional machine shop offering complete tooling support with over 50 years of combined experience.

Keystone’s precision metal stamping service combines the experience of our toolmakers with our dedication to quality to produce components that reliably exceed the standards of our customers. Using progressive tooling and compound/secondary tooling to produce a large variety of sheet metal pieces. We are able to offer quick turnarounds on prototypes and production runs. Our material list includes galvanized, galvannealed, cold rolled steel, hot rolled steel, stainless steel, aluminum, brass, bronze and copper. Presses have a range of 15 – 400 tons, maximum bed length of 108″, and a maximum bed width of 54″. We can produce parts with thicknesses ranging from .012″ to .375″ with close or precision tolerances.

To learn more about Keystone’s metal stamping service, please refer to the table below or contact us today.

| Title | Description | |

|---|---|---|

| General Capabilities | Contract Manufacturing Custom Metal Stamping |

Production Prototype |

| Industry Focus | Heavy Truck Appliance Construction Furniture |

Military Plumbing Wire Brush Vibration Control |

| Press Rating | 15 to 400 tons | |

| Press Speed | Up to 90 strokes/min | |

| Maximum Automatic Feed | 36 in Wide by 36 in Advance depending upon Thickness | |

| Maximum Press Bed Length | 108 in | |

| Maximum Press Bed Width | 54 in | |

| Part Thickness | .012″ Min | Up to .375″ |

| Part Tolerance (+/-) Die Tolerance (+/-) |

Hole ± .002” Other ± .005” / ±.010” / ±.030” ± .000 |

|

|

Die Types |

Progressive Single Hit Forming Dies Blanking Dies Secondary Dies |

|

|

Production Method |

Progressive Die The raw stock is fed into a single die that has multiple stations to insure perfect quality. Compound / Secondary |

|

|

Production Volume |

Specialty Production Shop Prototype High Volume Large Run |

Long Run Large Production Volume Run |

| Materials | Aluminum Brass Bronze Cold Rolled Steel High Strength Low Alloy Steel |

Bronze Pre-Finished Metals Stainless Steel HRP&O Copper |

| Stamping Product | Furniture Parts Fuses Hardware Heat sinks |

|

| Stamping Features | Coated coined Countersunk Embossed Enameled Heat Treated |

Numbering Shape Critical Tapped Threaded Flat |

| Additional Services Provided | Assembly DE burring Design Heat Treating Plating Packaging Powder Coating |

Tapping Trimming Pre-plated welding E-Cote Rivet |

| File Formats | AutoCAD (DWG,DWZ) AutoCAD (DWG,DXF) BMP – Bit Mapped Graphics DXF – Drawing Interchange Format, or Drawing Exchange Format GIF – Graphics Interchange Format IGES – Initial Graphics |

Exchange Specification, ANSI file format. JPG or JEPG – Joint Photographic Experts Group PDF – Portable Document Format Pro-E or Pro/Engineer (DRW,PRT,XPR) |